If you are a manufacturer that is looking for a way to increase productivity, efficiency, and, consequently, profits, then you must keep up with the modern world. And that, among other things, means investing in some automation solution that can help you stay competitive and meet those goals I have mentioned. The fact that you are here tells me that you are thinking about this already, and that you are quite interested in automating certain processes and thus making things easier.

Of course, while you are interested in this already, you certainly won’t jump right towards it, before getting answers to some important questions. For one thing, you want to understand the importance of automation in the first place. And then, you want to understand how to choose the right Robotic Integrator and how to generally get the right solutions for yourself. And, well, those are both, without a doubt, some quite important questions right there.

What we are going to do now is, naturally, answer those for you. This way, you will get a better idea about why it is that you may want to turn towards automation, as well as learn how to get the best solutions and be happy with the final outcomes. Take your time, therefore, to keep on reading and find out what you need to know about all of this, before taking any kinds of final steps.

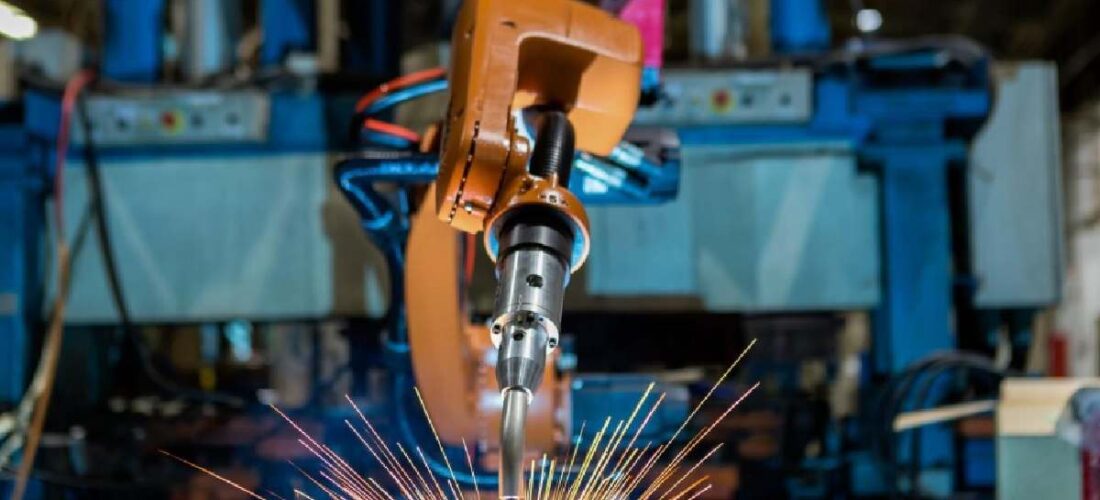

The Importance of Welding Automation

Clearly, we are going to begin with the question of why welding automation is so important in the first place. No doubt that you have heard of this option, and that you know it consists of using machines, robotics, and software solutions to perform those welding tasks with next to no manual intervention. Furthermore, you’ve most probably also heard that a lot of manufacturers are switching to this particular solution. Yet, you may not know why, and it is time for you to find out.

First things first, automated welding systems are much faster than, well, human welders. And not only that, but they can operate continuously, meaning there is no need to stop at any point, which is sure to further increase productivity. They can maintain consistent speed and reduce downtime between welds, all of which leads to a higher output and, of course, shorter production cycles. So, increased productivity is reason number one.

Here’s what robot welding is: https://en.wikipedia.org/wiki/Robot_welding

Moving on, automating this process is also going to ensure consistent quality. After all, the robots you can use will follow precise and repeatable paths, thus producing uniform welds. This is sure to reduce any kinds of quality issues, as well as eliminate the need for rework and scrap, and I am sure you understand just how big of a benefit this is.

Apart from all of that, this can also resolve your labor challenges. After all, skilled welders are in short supply, and automation allows you to reassign your skilled workers to some other, higher-value tasks, including supervision, programming, inspection and similar, while the robots are doing the repetitive tasks. All of this is sure to also improve workplace safety, as well as result in long-term cost savings through increasing efficiency, and decreasing errors and deficiencies.

How to Get the Right Solutions for You

The above should have given you a better idea about the actual benefits of automating your welding processes. What you want to do next, though, is figure out how to actually get the right solution for your manufacturing business. And, well, the main thing to do here is, of course, choose the right company that will provide you with the best solutions. Go here to get a guide on robotic welding that could help.

Of course, the very first thing you should do is understand your welding needs, thinking about factors such as production volume, part complexity, material type and thickness, as well as the available space. To put things simply, you have to know your needs, so that you can proceed towards getting the best solutions for yourself. So, take your time to define those needs before going any further.

Once that is done, though, we return to the main task that we have hinted at above. The task of actually finding and choosing the right robotic welding company that will provide you with the solutions you need. Start by searching for them online, and ask around, so as to create a list of potential candidates.

When the list has been created, you’ll be ready to start researching the professionals in more details. Check the types of automation solutions they are offering, the integration capabilities and the support they offer along the way. Then, check experience and reputation as well. Finally, get in touch, ask any questions you may have, and ultimately compare all the answers and all the info you’ve found, and make your choice.